What are the methods of piling?

1. Hammering

The impact energy of the pile hammer is used to overcome the resistance of the foundation soil to the pile, and the pile is driven to a predetermined depth, which is suitable for soft plastic or plastic cohesive soil. The main equipment used are pile frame, pile hammer, power equipment, etc. Commonly used pile hammers include drop hammer, single-action steam hammer, double-action steam hammer and diesel hammer. The hammer body of the drop hammer is made of cast iron and weighs 250 to 2000 kg. It is lifted by manpower or a hoist, and the piling is driven by the impact energy of the free fall of the hammer body.

The advantage is that the structure is simple, but the piling speed is slow. The single-action steam hammer uses the energy of steam or compressed air to lift the hammer body, and drives the pile by the impact energy of the free fall of the hammer body. A pile hammer.

The double-acting steam hammer is a cylinder fixed on the top of the pile, and the energy of steam or compressed air pushes the hammer body to move up and down in the cylinder. Because of its high impact frequency, it can not only drive piles, but also pull out piles, and is widely used in piling construction. There are two types of diesel hammers: rod type and cylinder type. Its working principle is similar to that of a diesel engine cylinder, and its piling efficiency is also high. It is also a more commonly used pile hammer. The weight of the pile hammer is an important parameter in piling construction.

The pile should be driven lightly with a heavy hammer, and the drop distance should not be too large, so as not to crack the top of the pile, or cause horizontal cracks within 1/3 of the pile length below the top of the pile; The pile body is absorbed, the work efficiency is low, and the pile head is easy to be broken. Therefore, the hammer weight should be carefully selected according to soil quality, pile weight and pile type.

During piling, in order to avoid the horizontal displacement of the piles driven first by being pushed by the piles driven later, the pile driving sequence should be arranged reasonably. When there are multiple rows of piles, the advancing direction can be changed one by one; the same row of piles can be driven at intervals; when large-scale piles are driven, generally start from the middle and gradually advance to the surrounding areas.

2. Vibration method

When driving a pile, a high-power vibratory pile driver is installed on the top of the pile, and the vibration force is used to reduce the resistance of the foundation soil to the pile. It has high piling efficiency in sandy soil and can also be used for sinking and pulling steel sheet piles and steel pipe piles.

3. Water jet method

Also known as the water jet piling method. It is an auxiliary method of hammer method and vibration method. Using high-pressure water flow, through the water jet pipe installed on the side of the pile or in the hollow pile, the soil layer around the tip of the pile is loosened to achieve the purpose of reducing the sinking resistance of the pile. Generally used in sandy soil, the efficiency is very high. When the pile tip sinks to about 1 to 1.5 meters away from the design elevation, the water should be stopped, and the pile should be sunk to the design elevation by hammering or vibration method.

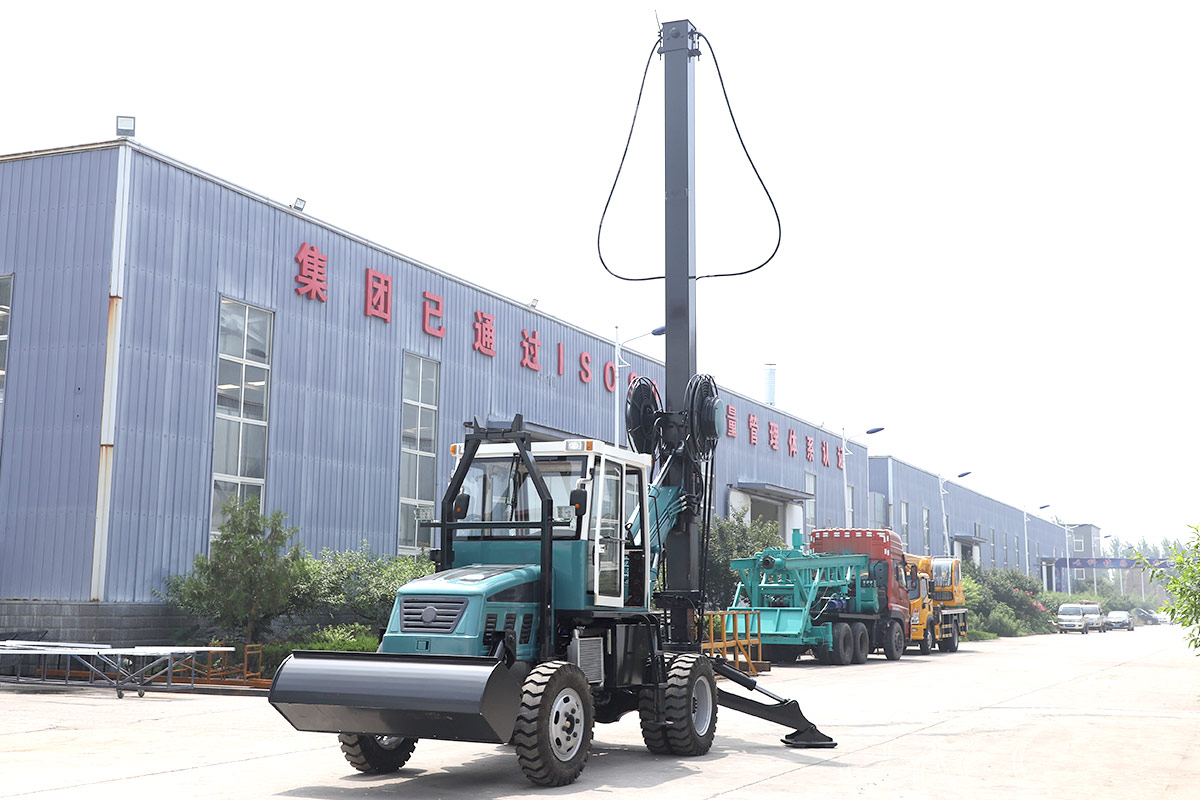

4. Pile pressing method

With the help of the dead weight of the pile frame and the weight on the pile frame, the pile is pressed into the soil through the reversal of the pulley. The piling method can reduce the noise and vibration of the foundation soil and adjacent buildings during hammering or vibration piling, and is suitable for relatively homogeneous soft soil foundations. In sandy soil and other hard soil layers, it is not suitable for use due to excessive resistance.

Due to the limitation of the height of the pile driving frame, each pile needs to be pressed in sections, so there are many joints. The new process of connecting piles using sulfur cement as a cement has been successful and popularized.